Natural wood is considered the most ubiquitous building material. This is because the strength to density ratio in natural wood is very high. It is a very interesting fact that the weight and height of trees are very high but still, it floats on the surface of the water. Several researchers and engineers are researching on dubbing natural wood as metallic wood. Porosity can be implemented for dubbing the properties of natural wood into metallic wood. Metallic woods are 4 times lighter than titanium with its equivalent strength. The porous construction of the metallic wood is very similar to the natural wood, that’s why it is given the name metallic wood. This metallic wood is being developed by the researchers, scientists, and engineers at Middle East Technical University in Turkey, the University of Cambridge, the University of Illinois in Urbana Champaign, and the University of Pennsylvania’s School of Applied Science and Engineering.

Source: University of Pennsylvania

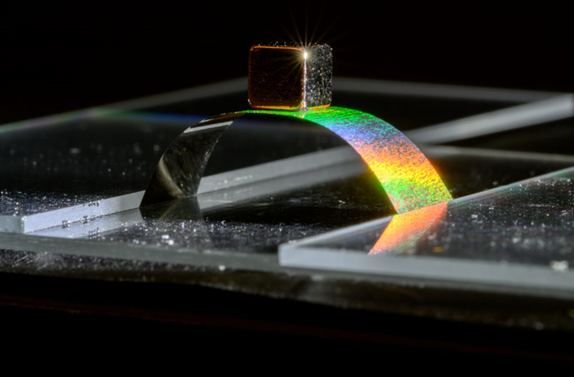

The figure above represents a strip of metallic wood that is 0.33 inch wide and 1 inch long, that is very thin as compared to the household aluminum foils. But in spite of that, it could support 50 times its own weight and there is no bucking observed in the metal strip. It is being observed that the same metallic strip could support more than six pounds of weight without breaking. The consistent strip of these materials could be used for building better devices. This new metallic wood is considered three times stronger than the previously obtained porous metal along with a 1000 times bigger nanolattice structure with a similar density. These materials could be efficiently used for separating biomaterials in diagnosing cancer treatments, flexible sensors, and protective coatings.

Properties of metallic wood

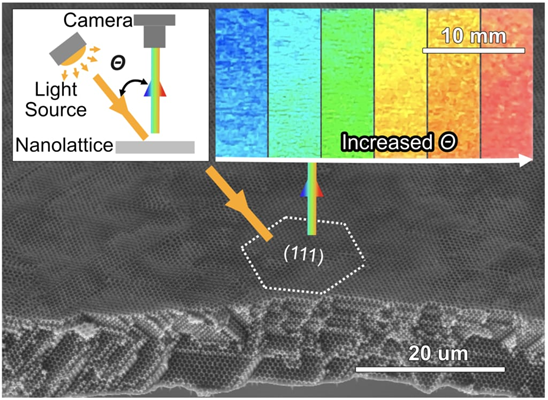

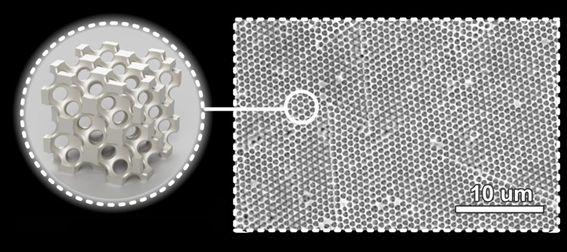

Metallic woods are a lattice of structured nanoscale nickels in cell-sized pores that are regularly spaced in such a way that the strength of the material is not compromised while reducing the density. The strength of metallic wood at every fraction of its weight is obtained as much as the strength of titanium because of the précised spacing of the gaps however the optical properties of the material are very unique. The size of the gap spaces is given the same as the wavelength of visible light. The interference of light after reflecting the metallic wood enhances specific colors. The changing enhanced color of the metallic wood depends on the reflection angle that provides it a dazzling appearance and hence can be used as a sensor.

Source: University of Pennsylvania

The density of metallic wood is similar to the natural wood along with its cellular nature. It includes porous cellular materials that are very dense and thick for holding the structure of the material. The porous part is responsible for supporting the biological functioning of the cell-like transporting. The obtained metallic wood is very similar to the natural wood in density and thickness along with strong metal structure and porous air gaps in the structure.

Inverted cracks and Nanoscale pores

However, there is a big problem that is needed to be solved regarding the metallic wood that is inverted cracks. An inverted crack can be considered as an excess of nickel atoms in the metallic wood filled in its nanoscale pores because of its unique properties. Inverted cracks are formed during the manufacturing of metallic wood. The initial template of metallic wood is made up of nanoscale spheres that are stacked over one another. Nanoscale pores are considered as the spine of the properties of the metallic wood; however, the template may include some sort of crack before the addition of nickel in the material. Nickel is filled at the gaps of the disrupted regular stacking pattern of the nanoscale spheres that may result in the formation of inverted cracks whenever we remove the template from the material.

Preparation of metallic wood

Nanoparticle solution can be used to form these kinds of material by evaporating the solution until we obtain a dry and regular stacked material from it. The water’s surface force is very strong that creates a big challenge while preparing the metallic wood material. This results in ripping of the particles and may often develop cracks in the material. It is a big challenge to prevent the formation of cracks in the structure of the material while preparing it. However, researchers developed a new technique through which the cracks could be avoided by keeping the template wet during the self-assembly process of the material. This strategy efficiently prevents the formation of cracks in the film, but the wet particles are locked in place with the help of electrostatic forces. After stabilizing the material, we could easily fill them up with metal.

These tiny plastic nanoparticle spheres are very small in size that is about a few nanometers in diameter. These spheres are suspended in the water. When the water is evaporated, we observe the settlement of nanoparticle spheres and they stack together like a cannonball that depicts a crystalline framework. These nanoparticle spheres could be infiltrated with the help of electroplating in which nickel is added to the thin layer of the hubcap’s chrome. After adding nickel to the structure, we wait for its settlement, these plastic nanoparticle spheres are dissolved in a solution that results in the formation of an open structured network of metallic wood. The metallic struts in the material include a width of about 10 nm and this type of complex structure could be formed only with the help of 3D printing. This method is very flexible and faster in regards to scalability. The synthesis of larger materials formed from these metallic woods is needed to be studied further regarding their behavior and characteristics; however, researchers have successfully developed a foil made up of this material. The metallic wood would be used in a variety of products like submarines, fighter jets, unmanned vehicles, and vehicle armor.

References

Billy Hurley (01 February 2019), “What is ‘Metallic Wood?’ Nickel, Plus Nano-Pores”, accessed on 4th July 2021, <https://www.techbriefs.com/component/content/article/tb/stories/blog/33788>

David Szondy (29 January 2019), “”Metallic wood” makes nickel as strong as titanium, but five times lighter”, accessed on 4th July 2021, <https://newatlas.com/metallic-wood-nickel-titanium/58234/>

Evan Lerner (24 June 2021), “Growing ‘Metallic Wood’ to New Heights”, accessed on 4th July 2021, <https://phys.org/news/2021-06-metallic-wood-heights.html?utm_source=webpush&utm_medium=push#>

Hrachya H. (08 April 2019), “Metallic Wood: New Material That Is As Strong As Titanium But 5 Times Lighter”, accessed on 4th July 2021, <https://www.overtdefense.com/2019/04/08/metallic-wood-is-a-new-material-that-is-lighter-and-stronger-than-titanium/>

Kate Winslet (30 June 2021), “Grow “Metallic Wood” to new heights”, accessed on 4th July 2021, <https://floridanewstimes.com/grow-metallic-wood-to-new-heights/295800/?amp>

Nagoor Vali (30 June 2021), “Growing ‘metallic wood’ to new heights — ScienceDaily”, accessed on 4th July 2021, <https://iconicverge.com/growing-metallic-wood-to-new-heights-sciencedaily/amp/>